|

Hebei Biaohui Rubber and Plastic Products Co., Ltd

|

Air Inflatable Double Packer for Permeability Lugeon Test of Bq Nq Hq Pq Wireline Drilling

| Payment Terms: | T/T,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Adapted to a wide range of B, N, H, P drilling hole diameters and other hole dia. can be customized. The packers are highly flexible and can be inflat

brief introduction

edit

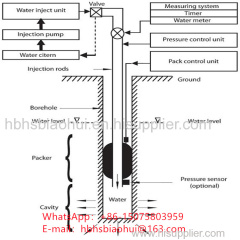

Water pressure test is a kind of in-situ test in which the water pressure is put into the borehole in a high-pressure way, and the development and permeability of rock mass fractures are known according to the calculation of water absorption of rock mass. The water pressure test is to isolate a certain length of drilling test section with a water stop device, and then use a fixed water head to press water into this section of drilling. The water seeps into the rock body through the cracks around the hole wall, and the final seepage volume will tend to a stable value. The strength of rock mass permeability can be determined according to the water pressure head, the length of the test section and the stable seepage volume. It is usually expressed in terms of water permeability q, and the unit is Lu. It is defined as: when the pressure of water pressure is 1MPa, and the water injected per meter length per minute is 1L, it is called 1Lu. Q=Q/(P * L), where q is the water permeability, Lu; Q is the pressure flow, L/min; P is the total pressure acting on the test section, MPa; L is the length of the test section.

Classification of water pressure test: simple water pressure test, single-point water pressure test and five-point water pressure test.

edit

1. Pre-test stage

Slowly raise the water pressure in the pipeline to the specified test pressure and stabilize it for 30min. During this period, if there is a pressure drop, water can be injected to supplement the pressure, which shall not be higher than the test pressure;

Check whether there is water leakage or damage at the pipe interface and fittings;

In case of water leakage and damage, stop the pressure test in time, find out the cause and take corresponding measures, and then retest the pressure.

2. Main test stage

Stop water injection and make up pressure, and keep it stable for 15min. When the pressure drop does not exceed the allowable pressure drop value after 15min, reduce the test pressure to the working pressure and keep it constant for 30min. Conduct visual inspection. If there is no water leakage, the hydraulic test is qualified. [1]

3, Main technical parameters:

Sealing hole diameter 30-200mm (can be processed according to user requirements)

Working pressure 1-10MPa (can be processed according to user requirements)

The working flow can be 3-4.5 tons of grouting per hour

Hole sealing depth 1-800m

Adapted to a wide range of B, N, H, P drilling hole diameters and other hole dia. can be customized. The packers are highly flexible and can be inflated with different fluids, durable and versatile. The deflated packer is put into the drilled borehol, then inflated with neutral gas or liquid through an inflation hose. The range of inflatable packers can be customized and rubber length depends on the work.

These single packers can be easily transformed into double packer.

II. APPLICATIONS:

1. Pressure Grouting in Fractured or Unconsolidated Borehole or Rock Formations

2. Water Infusion for Dust Control in Coal Mines

3. Methane Gas Control and Collection in Mines

4. Sealing Elements in Soil or Boreholes

5. Water Sampling Testing

6. Hydraulic Fracturing Testing

7. Permeability Testing

8. Quality Control Testing of Tubes

9. Bore-Hole Fluid Sampling,

10. Bore-Hole Wall Impression Testing

11. Industrial Piping Hydro-Testing,

12. Water Wells Repair

13. Aquifers Monitoring

III. STRUCTURE:

It is a versatile tool for a wide range of hole sizes and depths.

Standard construction includes steel metal parts and a reinforced rubber sleeve element, rubber grouting hose, water/air inflation hose, manual water pump for supplying inflation water, straddle steel pipes, etc.

Rubber membrane reinforced

Abrasive resistant rubber

Extensible Steel fabric

All above elements, size and length can be customized

| SIZE | I.D(mm) | O.D(mm) | Expansion Range(mm) | Aperture(mm) | W.P(Mpa) | T.P(Mpa) | B.P(Mpa) |

| φ16-2 | 16±0.5 | 30±1.5 | 50 +8/-2 | 40 | 8 | 16 | 32 |

| φ16-4 | 16±0.5 | 36±1.5 | 50 +8/-2 | 40 | 20 | 30 | 40 |

| φ19-2 | 19±0.5 | 36±1.5 | 60 +8/-2 | 45 | 8 | 16 | 32 |

| φ19-4 | 19±0.5 | 40±2.0 | 60 +8/-2 | 45 | 20 | 30 | 40 |

| Φ22-2 | 22±0.5 | 39±2.0 | 80 +8/-4 | 50 | 6 | 12 | 24 |

| Φ22-4 | 22±0.5 | 45±2.0 | 80 +8/-4 | 50 | 20 | 30 | 40 |

| Φ25-2 | 25±0.5 | 42±2.0 | 90 +8/-4 | 65 | 6 | 12 | 24 |

| Φ25-4 | 25±0.5 | 48±2.0 | 85 +8/-4 | 55 | 16 | 24 | 32 |

| Φ32-2 | 32±0.5 | 50±2.0 | 90 +8/-4 | 60 | 6 | 12 | 24 |

| Φ32-4 | 32±0.5 | 54±2.0 | 90 +8/-4 | 60 | 16 | 24 | 32 |

| Φ38-2 | 38±0.5 | 55±2.0 | 95 +8/-4 | 65 | 5 | 10 | 20 |

| Φ38-4 | 38±0.5 | 60±2.0 | 95 +8/-4 | 65 | 16 | 24 | 32 |

| Φ45-2 | 45±0.5 | 63±2.0 | 100 +8/-4 | 75 | 4 | 8 | 16 |

| Φ45-4 | 45±0.5 | 69±2.0 | 100 +8/-4 | 75 | 16 | 24 | 32 |

| Φ51-2 | 51±0.5 | 69±2.0 | 110 +8/-4 | 90 | 4 | 8 | 16 |

| Φ51-4 | 51±0.5 | 75±2.0 | 110 +8/-4 | 90 | 16 | 24 | 32 |

| Φ64-2 | 64±0.5 | 84±2.0 | 120 +8/-4 | 100 | 3 | 6 | 12 |

| Φ64-4 | 64±0.5 | 90±2.0 | 120 +8/-4 | 100 | 8 | 12 | 16 |

| Φ76-2 | 76±0.5 | 94±2.0 | 130 +8/-5 | 110 | 3 | 6 | 12 |

| Φ76-4 | 76±0.5 | 99±2.0 | 130 +8/-5 | 110 | 8 | 12 | 16 |

| Φ89-2 | 89±0.5 | 109±2.0 | 140 +8/-5 | 130 | 3 | 6 | 12 |

| Φ102-2 | 102±0.5 | 122±2.0 | 160 +8/-5 | 150 | 3 | 6 | 12 |